- SYSTEM 16 METRIC SERIES

THE WALTER

SYSTEM 16

METRIC(MM)WELDING

TABLES

.jpg)

D16 STEEL TABLE

D16 CAST IRON TABLE

D16 STEEL NITRIDED TABLE

D16 CAST IRON NITRIDED TABLE

SYSTEM 16 METRIC ACCESSORY SETS

VIEW ALL ACCESSORY SET

D16 SET1(28 Piece kit)

D16 SET2(40 Piece kit)

D16 SET3(68 Piece kit)

D16 SET4(96 Piece kit)

D16 SET5(116 Piece kit)

- SYSTEM 28 METRIC SERIES

THE WALTER SYSTEM 28 METRIC(MM)WELDING TABLES

D28 STEEL TABLE.jpg)

D28 CAST IRON TABLE

D28 STEEL NITRIDED TABLE

D28 CAST IRON NITRIDED TABLE

SYSTEM 28 METRIC ACCESSORY SETS

VIEW ALL ACCESSORY SET

D28 SET1(28 Piece kit)

D28 SET2(40 Piece kit)

D28 SET3(68 Piece kit)

D28 SET4(96 Piece kit)

D28 SET5(116 Piece kit)

The Welders Blog

-

2025-10-14

Repair welding doesn’t have to mean chaos and cleanup. With the right tools — the Walter 3D Welding Table, Professional Steel Plasma nitriding welding platform, and Welder 3D Durable Nitriding welding table System — every repair can be as clean, precise, and efficient as production work.

Supported by the Steel S355 Durable Nitriding welding table System in stock and Nitrided Surface 3D Modular Welding Table, your shop will experience a transformation in productivity, accuracy, and surface quality.

For welders who demand results, not excuses, plasma-nitrided modular platforms are the ultimate foundation for precision repair work. -

2024-12-21

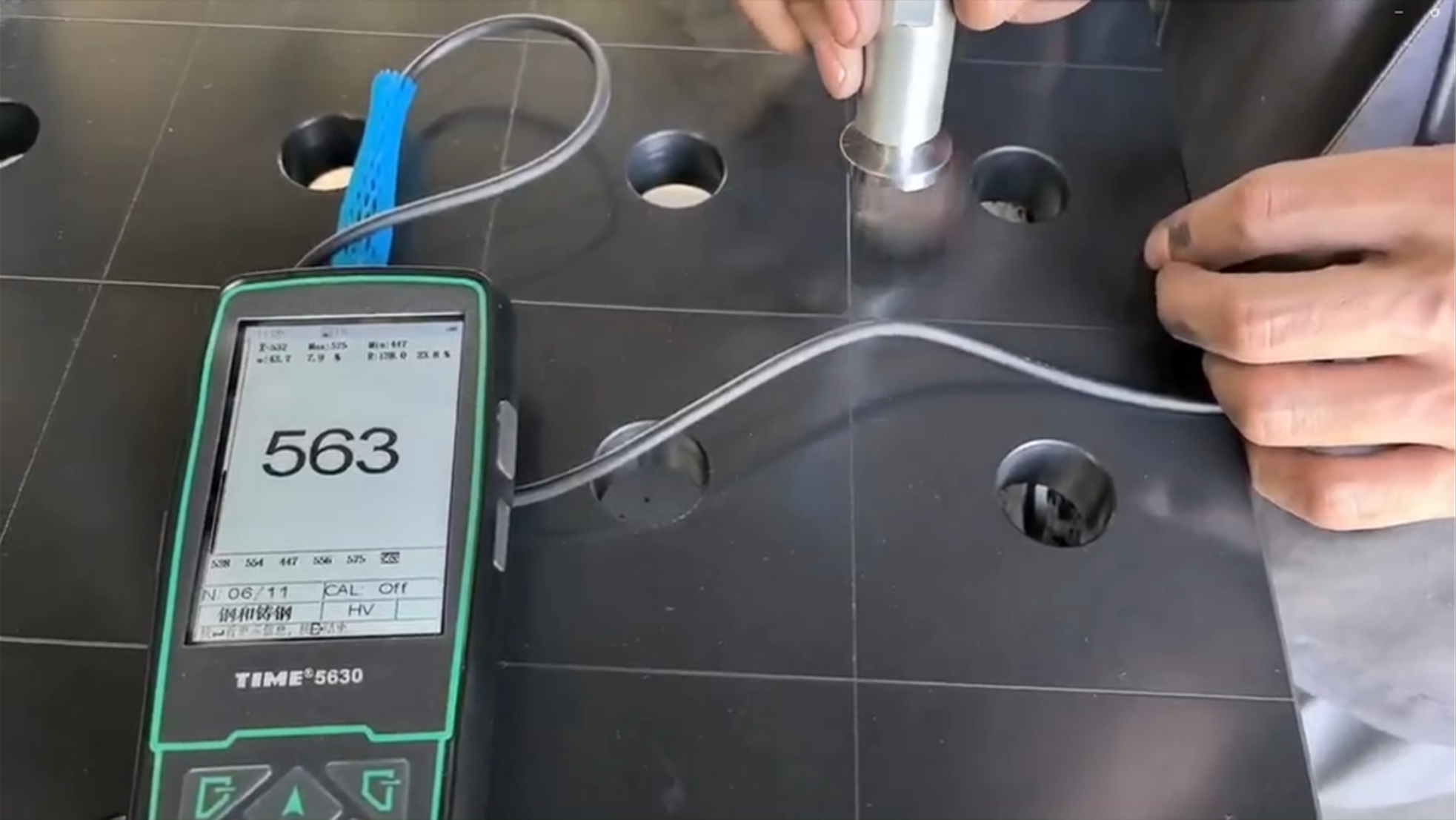

These are videos of steel tables and nitrogen-processed steel tables from our factory. The video shows the measurement of the original material hardness and the hardness after nitrogen treatment using instruments.

-

2025-10-14

Repair welding doesn’t have to mean chaos and cleanup. With the right tools — the Walter 3D Welding ......

-

2024-12-21

We tested the nitrided tabletop by hitting it with a solid steel plate of regular size. After multip......

-

2024-12-21

These are videos of steel tables and nitrogen-processed steel tables from our factory. The video sho......

-

Plasma Nitriding Process for Q355 Steel and HT300 Cast Iron

2024-12-19

1. Overview of Plasma Nitriding

Plasma nitriding is an advanced thermochemical surface treatment th...... -

2024-12-19

The Evolution of Welding Gear Back in the 1940s, before the invention of modern welding jackets, wel......

-

Why Automation Integrators Choose WALTER 3D Welding Tables for Robotic Precision and Flexibility

2025-11-26

This article explores why automation equipment integrators rely on WALTER 3D welding tables for robotic and automated welding. Focusing on modularity, repeatability, durability, and surface accuracy, it covers setup processes, real-world automotive cases, and expert integration tips for the smart manufacturing era.

-

How WALTER 3D Welding Tables Empower Small & Medium Manufacturers for Efficient, Flexible Production

2025-11-26

This article details how small and medium manufacturers use WALTER 3D welding tables to improve flexibility, speed up changeovers, and maintain weld quality in fast-paced production settings. With practical setup guides, productivity tips, and a metal furniture factory case, the article shows how modular tables and robust fixtures help SMEs compete and grow.

-

2025-11-26

This article outlines why overseas project contractors prefer WALTER 3D welding tables for complex structural welding. Highlighting the benefits of modular design, heavy-duty construction, anti-corrosion coating, and jobsite flexibility, it provides actionable setup guidance, troubleshooting solutions, and a real-world bridge construction case. WALTER tables help ensure weld durability and project efficiency worldwide.

-

2025-11-26

This in-depth guide explores why weld spots remain durable when using WALTER 3D welding tables. Covering essential advantages like modular design, precision clamping, S355 steel strength, and anti-corrosion finishes, it gives practical steps and tips for setup, operation, and troubleshooting. Real-world cases show how WALTER tables cut rework rates and maximize productivity for industrial users.

-

The Ultimate Secret: How Veteran Welders Cut Welding Table Costs and Secure Reliable Supply

2025-11-25

Veteran welders share the ultimate secret to lowering welding table costs and securing a stable supply: choose Steel S355 3D welding table from a trusted global supplier. We are looking for worldwide partners. Whatsapp/wechat:+86 15530775091

-

How Veteran Welders Avoid Common Pitfalls: Choosing the Best Welding Table for Cost and Quality

2025-11-25

Explore how veteran welders avoid the traps of high welding table costs and unreliable supply by choosing Steel S355 3D welding table. Our company is a professional global supplier seeking new partners. Whatsapp/wechat:+86 15530775091

-

Unlocking the Secrets: How Experienced Welders Save Money and Time with the Right Welding Table

2025-11-25

Unlock the secrets of experienced welders: find out why Steel S355 3D welding table is the top solution for cutting costs and gaining reliable supply. Our company is your premium global partner for welding tables. Join our network! Whatsapp/wechat:+86 15530775091

-

The Veteran Welder’s Guide: How to Avoid High Costs and Unstable Suppliers in Welding Tables

2025-11-25

This guide uncovers the real cost drivers and supplier pitfalls veteran welders have learned to avoid. See why Steel S355 3D welding table is their go-to choice for consistent savings and quality. Our company is a premium global welding table supplier seeking worldwide partners. Whatsapp/wechat:+86 15530775091

WALTER Series

Information

Customer Reviews

Customer Gallery

Terms & Conditions

Privacy Policy

Return Policy

About Us

.jpg)

(1).jpg)

.jpg)

.JPG)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)